|

A |

adameve (@adameve) |

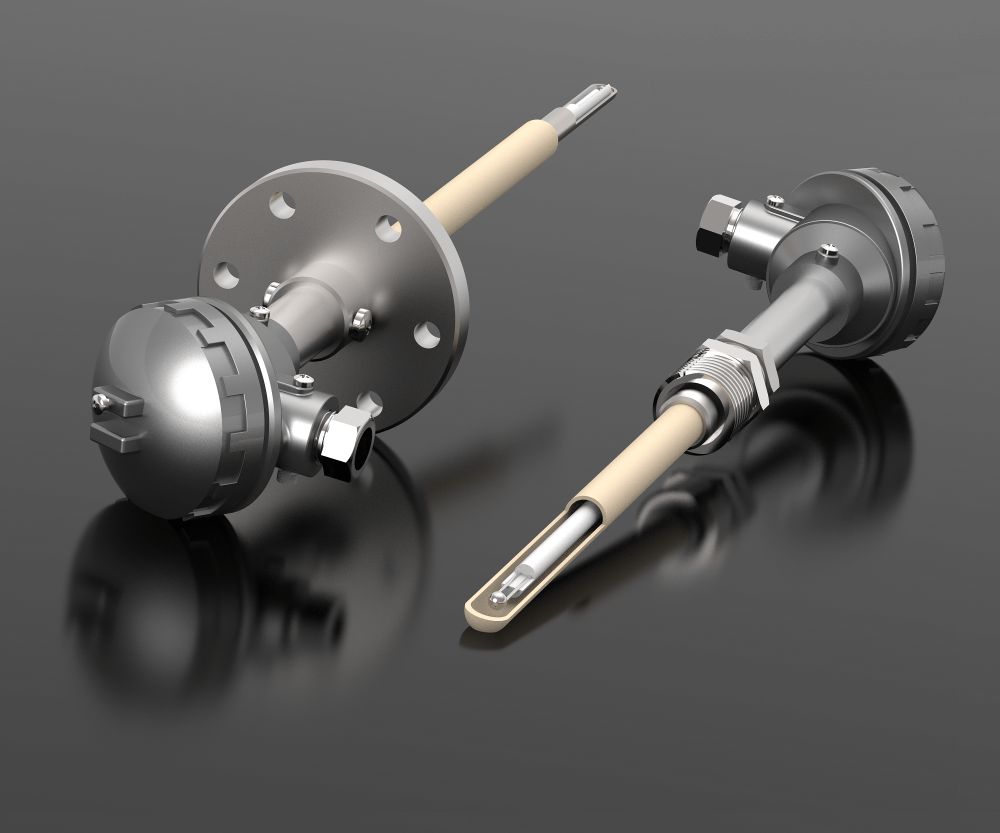

The temperature sensors are composed of distinct metal alloys, which are ingeniously designed. They form a hot junction at one end while the other remains open- a setup critical for precise temperature measurement within industrial processes.

Essentially, these sensors act as vigilant observers within your industrial domain. They convert thermal changes into signals, offering insights into the dynamic temperatures of your operational processes.

In this assembly of industrial expertise, let's acknowledge a moment to appreciate the significance of these thermocouples and the craftsmanship of the thermocouple manufacturer.

They're not just sensors but silent sentinels providing invaluable data to maintain operational efficiency and uphold precision in industrial operations. Welcome to the world where metals decode temperatures, empowering us with crucial insights for industrial excellence.

How to go for the best thermocouple manufacturers?

Online Search: Look up thermocouple manufacturers online. Check their websites and what people say about them.

Ask People: Talk to others in your industry. See if they know good companies that make thermocouples.

Check Certificates: Look for certificates or awards. They usually mean the companies are good at what they do.

Experience Matters: See how long they've been making thermocouples. More years often mean more knowledge.

Talk to Them: Reach out to a few companies. Ask if they can make the thermocouples just how you want them.

Compare Prices: Ask for prices from different companies. Look for good quality that fits your budget.

Read Reviews: See what others say about these companies. Happy customers mean they're probably doing something right!

What are the parameters the thermocouple manufacturer checks in their production process?

Choosing the Right Metals: The thermocouple manufacturer picks metals that work well together for the wires.

Joining Carefully: They connect these metal wires carefully at the hot spot to make the thermocouple work well.

Making Sure It Measures Right: They double-check to ensure the thermocouple gives the correct temperatures.

Checking Quality: They keep an eye on the thermocouples as they're made to make sure they're good quality.

Protecting It: They cover and save the spot where the metals meet so that it's not affected by outside stuff that could mess up the temperature readings.

Testing It a Lot: They test the thermocouples several times to ensure they work perfectly.

Following Rules: They follow rules and standards to ensure the thermocouples are safe and sound.

Making It Better: They always try to find ways to make the thermocouples even better by improving them.

What are the types of thermocouples these manufacturers produce?

Base Metal Thermocouples with Thermowells: These are basic and affordable, often protected for durability.

MI (Mineral-Insulated) Thermocouples are super tough and accurate, packed in a mineral-filled metal tube.

Noble Metal Thermocouples: These use fancy metals like platinum for precise temperature readings in labs or high-heat settings.

Refractory thermocouples: Made to handle crazy high temperatures, they are great for places like kilns or aerospace.

Special Custom Thermocouples: Manufacturers can create unique ones for specific needs, like special designs or alloys for different industries.

What are the standards before choosing a thermocouple?

Before choosing a thermocouple, consider these standards:

Temperature Range: Ensure the thermocouple can measure the temperatures needed for your application without exceeding its limits.

Chemical Resistance: Check if the thermocouple or its protective sheath material can withstand exposure to chemicals in your environment without corroding or degrading.

Abrasion and Vibration Resistance: Assess if the thermocouple can handle any mechanical wear from abrasion or vibration in its placement location to ensure longevity.

Installation Requirements: Ensure the thermocouple fits your existing equipment and installation spaces. Existing holes or spaces might determine the probe diameter or length needed for compatibility.

What are the rigorous quality control processes and adherence these thermocouple manufacturers follow?

Checking Materials: They ensure the metals and stuff they use are top-notch and work together correctly.

Testing Accuracy: They check if the thermocouples measure temperatures accurately by comparing them to known standards.

Making the Connection Right: They're super careful when joining the metals together to ensure the thermocouple works well.

Trying in Tough Conditions: They test the thermocouples in all conditions to see if they can handle it.

Making Sure It Works: Before sending them out, they do lots of tests to make sure the thermocouples work perfectly.

Following Rules: They stick to the rules and get certifications to ensure the thermocouples are good and safe.

Keeping Records: They write down everything they do so they can always check and improve how they make thermocouples.

Summary The world of thermocouple manufacturing is a testament to precision, innovation, and adaptability. Companies like Tempsens Instruments (I) Pvt. Ltd. are good at making thermocouples. They're focused on ensuring these temperature tools are top-notch for all sorts of jobs in different industries. Their commitment to quality and making specialized thermocouples for other needs makes them stand out. As industries change and need more accurate temperature readings, companies like Tempsens keep developing better ways to measure heat. They're the go-to team for ensuring things stay at the right temperature in places like airplanes, cars, hospitals, factories, and more.

Visit: https://tempsens.com/catalog/contact-temperature-sensors/thermocouples.html